Cleaning and Disinfection of Poultry Houses

"last update: 17 Nov. 2024"

- DISINFECTION PROGRAMME

A-TERMINAL DISINFECTION PROGRAMME FOR Animal House

B-CONTINUOUS DISINFECTING PROGRAMMES

C-SPECIAL DISINFECTION PROGRAMMES

➡️Terminal Disinflation.

- FOR NORMAL DISINFECTION ROUTINES

- Use a knapsack sprayer, pressure washer at a low-pressure setting (30 psi) with a fan jet or for larger premises an orchard sprayer.

- Disinfect all removable equipment at a rate of 300 ml/m2, and replace in cleaned house, then disinfect the cleaned house.

- Pay particular attention to corners, cracks, seams and porous surfaces.

- Ensure that all sides of supporting posts are covered.

- Spray into the apex of the roof and work down the walls to the floors.

- On completion of disinfection, close all doors.

- Place foot dips at entrances.

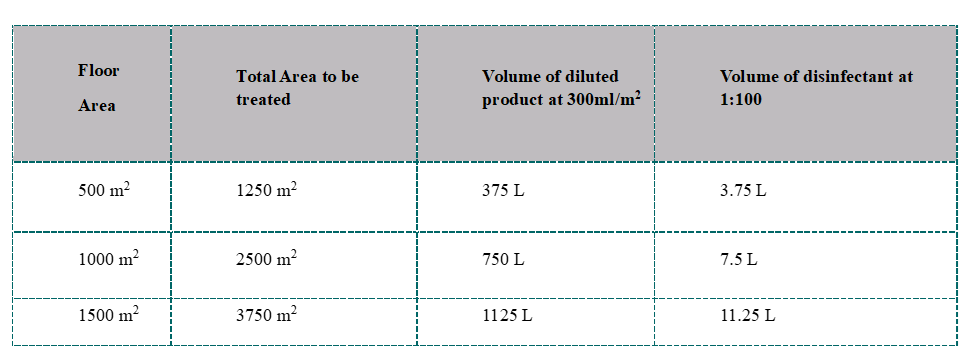

- Below is a table showing the amount of product required to disinfect broiler house of different sizes. As a guide for total area which includes walls, floor and roof is 2.5 times the floor area.

➡️AERIAL DISINFECTION

- . To control any contamination that might have been re-introduced with articles

- . To disinfect areas which are inaccessible to normal procedures, either by virtue of their position or proximity to electrical supply or similar.

- To help reduce any dust etc. which has been created

- To reduce the airborne spread of pathogens and other micro-organisms.

- To reduce levels of dust.

How can we achieve Aerial Disinfection?

➡️spraying

1. knapsack sprayer or pressure washer. This produces relatively large particles, which have a higher wetting capacity, but stay in the air for less time.

2. Misting (This is also known as cold fogging.)

3- Ultra-low volume fogging machines ULV

• This type of fogging machine can produce extremely small droplets with diameters ranging from 1–150 μm. ULV

• Machines are used for applying pesticides, herbicides, fungicides, sterilizers, and disinfectants amongst other chemicals.

4- By thermal fogging

• Like misting but involving heating of the disinfectant to produce a fine vapor.

• The small particle gives the best penetration and suspension.

• The use of thermal fogging is accepted practice for the final stage of full disinfection programs.

• This method of disinfectant application can be rapid and does not involve large volumes of liquids in buildings where equipment and litter are already installed.

• The drawback of the low volumes that are applied in this way is that there is insufficient penetration of organic matter and porous surfaces for thermal fogging to be effective for primary disinfection, its successful use needs to follow thorough clean out, wash down and spray disinfection.

➡️What Disinfectants can be used?

• Glutaraldehyde-QAC Ammonium mixtures

• QAC

• Virkon S + Fog enhancer (polyethylene glycol)

➡️Not efficient enough or safe enough for common use.

Hydrogen peroxygen, peracetic acid and non-halogen oxygen releaser - which is made up into solution. Has proven high levels of activity against a wide range of common poultry pathogens. It is safe in use for both operators and poultry. As a result, it can be used in terminal disinfection programs or while birds are still in the buildings.

➡️Fumigation:

When allowed, formalin fumigation should be carried out by trained personnel, following local safety legislations and guidelines. Fumigation should be carried out as soon as possible after disinfection; surfaces should be damp and the house warmed to a minimum of 21˚C and an RH more than 65%.The house should be sealed for at least 24 hours, then ventilated well to get rid the irritating formalin odder. Fumigation should be repeated after the litter has been spread.