Cleaning and Disinfection of Poultry Houses

| Site: | EHC | Egyptian Health Council |

| Course: | Vet. Public Health and Preventative Medicine Guidelines |

| Book: | Cleaning and Disinfection of Poultry Houses |

| Printed by: | Guest user |

| Date: | Tuesday, 24 December 2024, 1:20 AM |

Description

"last update: 17 Nov. 2024"

Table of contents

- - Acknowledgement

- - Glossary

- - Scope

- - Introduction

- - Purpose

- - Procedure

- - Factor affecting cleaning procedure

- - Common Floor Treatments Poultry Houses

- - DISINFECTION PROGRAMME

- - HOW DISINFECTION WORKS

- - CONSIDERATIONS WHEN SELECTING A DISINFECTION PROCESS

- - Factors affecting the efficiency of Disinfectant

- - Factors affecting disinfectant efficacy in the field

- - References

- Acknowledgement

We would like to acknowledge the committee of National Egyptian Guidelines for Veterinary Medical Interventions, Egyptian Health Council for adapting this guideline.

Executive Chief of the Egyptian Health Council: Prof. Dr Mohamed Mustafa Lotief.

Head of the Committee: Prof. Dr Ahmed M Byomi

The rapporteur of the Committee: Prof. Dr Mohamed Mohamady Ghanem.

Scientific Group Members: Prof. Dr Nabil Yassien, Prof. Dr Ashraf Aldesoky Shamaa, Prof. Dr Amany Abbas, Prof. Dr Dalia Mansour, Dr Essam Sobhy Dr Mohamed Elsharkawy, Prof. Dr Gamal A. Sosa., Dr Naglaa Radwan, Dr Hend El Sheikh

Editor/Author: Prof. Dr Usama M. K. Zahran

- Glossary

➡️STERILISATION: A process designed to kill all types of organisms with a probability that only one organism will remain from a starting count of 1,000,000,000. A process which kills all organisms present, including spores. Sterilization can only be reliably or repeatedly guaranteed using extreme physical/ chemical methods, e.g. placing instruments in an effective autoclave and subjecting them to high temperatures and steam pressures for extended time.

➡️Disinfection: A process that eliminates many or all pathogenic microorganisms, except bacterial spores, on inanimate objects.

➡️Decontamination: Decontamination renders an item or material safe to handle. It is a general term that includes cleaning, disinfection, and sterilization. They are key components of routine biosecurity in poultry farming aiming at disease prevention or spread reduction, killing any disease organisms like virus, bacteria, parasite, mold that might be present on a farm at the end of a production cycle or after disease outbreak allowing safe re-population of a farm.

➡️BIOCIDE: The general terms “biocide”, “germicide”, or “microbicide” refer to a substance or product that destroys or inhibits the growth or activity of living organisms. This includes disinfectants, sanitizers, antiseptics, and sterilant.

These antimicrobial products vary in their ability to destroy microorganisms.

The suffix –cide or -cidal (e.g., bactericide, virucidal, fungicide, sporicidal, tuberculocidal) reflects a killing action on a particular microorganism class.

The suffix –static (e.g., bacteriostatic, virostatic, sporostatic) is used if the product only inhibits the growth or replication of the organism.

➡️Cleaning: involves the physical removal of visible contamination from surfaces. Soaps and detergents bind to oils, soil and organic material so it can be rinsed away. Some cleaners can disrupt the lipid components (e.g., cell membrane or viral envelope) of certain pathogens. Physical action with detergent gives the removal of organic material and 99- 99.9% of organisms present.

- Scope

With the rapid development of the poultry industry in Egypt, various types of poultry farms (small scale producers, medium and large scale poultry producers) are constantly increasing. Therefore, the use of disinfectants to disinfect chicken farms, chicken houses and the environment is an important part of sanitation and epidemic prevention work. These guidelines are intended to help create farming conditions that prevent or minimize the occurrence and spread of infections and to promote the effective and safe use of drugs.

The overall purpose of the guideline is to help veterinarians, poultry growers, and farm workers who are responsible for sharing biosecurity concepts, measures and techniques with various audiences.

- Introduction

Keeping poultry houses, coops, and other enclosures clean is one of the best ways to prevent germs from spreading among poultry flocks.

Effective cleaning and disinfection is an essential component of good hygiene and thus one of the key biosecurity measures for disease control. This should be carried out from time to time to reduce the build –up of pathogenic organisms and a disinfectant known to be effective against a large range of pathogens should be used regularly for prevention of ingress of the infection.

Properly performing cleaning and disinfection (C &D) processes decreases pathogen levels on surfaces and reduces exposure risks.

• C&D is an essential component of biosecurity on farms

• C&D is critical for disease containment and elimination during disease outbreaks and also serves as a layer of protection against novel or emerging diseases.

However, the C&D process is often not done correctly. When efforts are ineffective, the destruction of disease-causing organisms can be inadequate, resulting in exposure to disease agents and further spread of microorganisms.

Successful C&D involves understanding the key principles and steps for the process, choosing the best method, and recognizing any limitations. This document addresses this information as well as factors to consider when setting up a C&D program, common failures in disinfection programs, and how to address health and safety issues.

- Purpose

The first thing to be done for profitable production in poultry facilities (poultry houses, hatcheries, slaughterhouses, transport vehicles, food and feed stores) is to minimize the emergence and spread of diseases. Poultry disinfection prevents the risk of contamination of living organisms, reduces the use of antibiotics and ensures the sustainability of production. This Guideline provides information for Cleaning and Disinfection working team and other personnel associated with cleaning and disinfection activities in poultry farms. The burden of disease in poultry can be reduced through the implementation of infection prevention strategies.

The general principles discussed in this document are intended to serve as a basis for making sound decisions regarding cleaning and disinfection. It is important to evaluate each situation and adjust procedures to the risks present in the situation.

- Procedure

➡️ When choosing a disinfectant, consider these characteristics

• Cost.

• Efficacy.

• Activity with organic matter.

• Activity in hard water

• Toxicity (relative safety to animals).

• Residual activity.

• Effect on fabrics & metals.

• Activity with soap.

• Solubility (Acidity, Alkalinity, PH).

• Contact time

• Temp. (Choose disinfectant which is active at low temp.)

➡️Criteria of the Ideal Disinfectan

An effective disinfectant is non-poisonous relatively fast at killing micro-organisms, working in adverse environmental condition.

➡️Pre cleaning procedures

• Allow a 2 week down time for cleanup.

• Keep the supply for electric current off before beginning of cleaning process.

• Spraying of insecticide

• Equipment, and all surfaces should be sprayed with insecticide

• Not allow chance for pests to migrate.

• All dust, debris, and dirt must be removed from fan shafts, beams, and exposed areas of unrolled curtains in open-sided houses, ledges, and walls.

• For the best results use a brush (or blower) so that the dust falls onto the litter.

• Pre-spray

- A low-pressure sprayer

- Spray a detergent solution.

- From ceiling to floor, to dampen down dust.

- Before bedding and equipment are removed.

- In open-sided houses, the curtains should be closed first.

• equipment

- All equipment and fittings (drinkers, feeders, fences, etc.) should be removed from the building and placed on the external concrete area.

- Automatic feeders and nipple drinkers should be raised during house cleaning.

- Leave it outside exposed to sun.

• Remove Bedding

- All bedding and debris must be removed from within the house.

- Trailers should be placed in/or near the house and filled with soiled bedding.

- The full trailer or dumpster should be covered before removal to prevent dust and debris from blowing around outside.

- Vehicle wheels must be brushed, and spray disinfected on leaving the house.

- High pressure sprayers may be effective to remove heavy accumulation of urine and feces or for cleaning porous surfaces (e.g., concrete).

- However, in cases of highly infectious or zoonotic pathogens, high pressure systems should be avoided or used with caution to avoid further dispersal of the pathogen or risk to the applicator

- Factor affecting cleaning procedure

1 -pre cleaning

2- High water temperature increase efficiency of cleaning

3-Cleaning compound

4- Time

5- Number of cycles

6- Force of application

➡️Cleaning procedure

• Pre rinse

• Rinse

• Soaking and detergent

• Post rinse.

➡️Cleaning operation

- A correctly performed cleaning operation eliminates 70-90 % of microbes.

- crucial factor in the effectiveness of poultry disinfection

- Note One gram of dust contains 200 000 to 800 000 coli form bacteria Also one gram of Bedding contains 7.9 billion coli form bacteria.

➡️Washing

- Wash the house thoroughly. The washing procedure is best accomplished using a high-pressure spray washer. (Be careful; high pressure washers can damage ceilings and curtains

- A pressure washer with foam detergent should be used to remove the remaining dirt and debris from the house and equipment.

- Steam cleaning with hot water alone is also a highly effective way to disinfect if you have the necessary equipment. After disinfecting, allow the house to dry completely.

- Make sure the detergent used is compatible with the compound you choose to disinfect with later.

➡️Rinsing

-Rinse with clean fresh water, again using a pressure washer.

- Wastewater should be disposed of hygienically to avoid any recontamination of the house.

-All equipment removed from the house must also be soaked, washed and rinsed.

- Cleaned equipment should then be stored under cover.

➡️NB

- Remember to cover fan motors, switch boxes, outlets, and other electrical equipment before washing down the house. (Clean these types of equipment with a blower, dry brush, or rag before covering them.)

- Start at the top of the house and work down. Be sure to clean off ledges, braces, air inlets and all other places where dust, dirt and litter accumulate.

- Be sure to thoroughly clean and disinfect feeders, hoppers and feed bins.

- Also, remove the feed bin boot and clean out any remaining feed.

- Don't forget to clean and disinfect the water. Flush out water lines and clean out tanks, proportioners, medicators, etc.

- Let as much light and air into the house as possible during your down time. Of course, do not allow wild birds or any other animals to enter the house at any time, but especially after it has been disinfected.

- Clean up the area around the outside of the house. Keep vegetation surrounding your poultry structures cut short. Disinfect 10 meters around the outside of your buildings.

➡️Disinfection of Water Systems:

Clean and high-quality water to be provided to the animals is very important for the animals in the poultry house to benefit from feed, to reduce the use of antibiotics and to prevent digestive problems. To ensure water hygiene, biofilm layer formation is undesirable. To prevent this, cleaning of the water system, use of effective disinfectants and continuous control of water.

➡️Feeding system

- Scrape and scrub the feeding system to completely remove all the old feed

- Remove the feed bin boot and clean out any remaining feed.

- Soaking, foaming, rinsing.

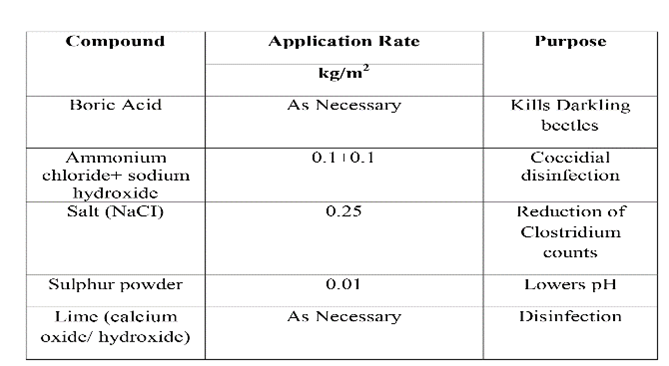

- Common Floor Treatments Poultry Houses

➡️Personnel Health and Safety

- Personal protective equipment (PPE) should always be used when preparing and applying disinfectants.

- At a minimum, this should include eye protection and gloves.

- Water-resistant disposables outwear (e.g., coveralls, boots) should be strongly considered. Respiratory protection (e.g., masks, possibly respirators) should be worn when preparing powdered formulations or for products with strong odors.

- Personnel should always wash their hands after C&D procedures – even if gloves were worn.

- DISINFECTION PROGRAMME

A-TERMINAL DISINFECTION PROGRAMME FOR Animal House

B-CONTINUOUS DISINFECTING PROGRAMMES

C-SPECIAL DISINFECTION PROGRAMMES

➡️Terminal Disinflation.

- FOR NORMAL DISINFECTION ROUTINES

- Use a knapsack sprayer, pressure washer at a low-pressure setting (30 psi) with a fan jet or for larger premises an orchard sprayer.

- Disinfect all removable equipment at a rate of 300 ml/m2, and replace in cleaned house, then disinfect the cleaned house.

- Pay particular attention to corners, cracks, seams and porous surfaces.

- Ensure that all sides of supporting posts are covered.

- Spray into the apex of the roof and work down the walls to the floors.

- On completion of disinfection, close all doors.

- Place foot dips at entrances.

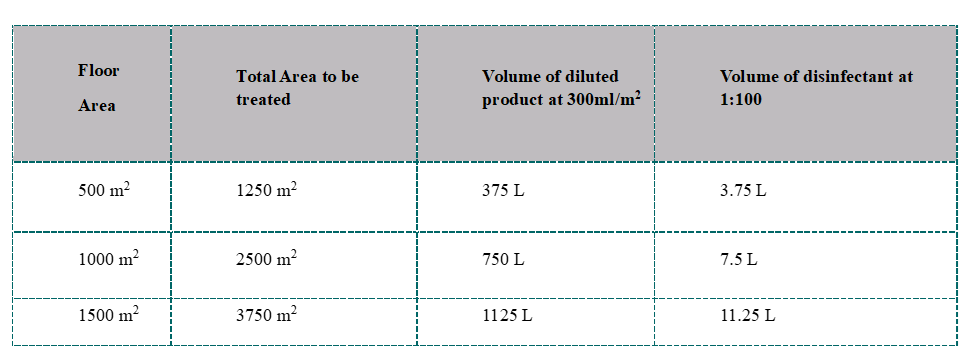

- Below is a table showing the amount of product required to disinfect broiler house of different sizes. As a guide for total area which includes walls, floor and roof is 2.5 times the floor area.

➡️AERIAL DISINFECTION

- . To control any contamination that might have been re-introduced with articles

- . To disinfect areas which are inaccessible to normal procedures, either by virtue of their position or proximity to electrical supply or similar.

- To help reduce any dust etc. which has been created

- To reduce the airborne spread of pathogens and other micro-organisms.

- To reduce levels of dust.

How can we achieve Aerial Disinfection?

➡️spraying

1. knapsack sprayer or pressure washer. This produces relatively large particles, which have a higher wetting capacity, but stay in the air for less time.

2. Misting (This is also known as cold fogging.)

3- Ultra-low volume fogging machines ULV

• This type of fogging machine can produce extremely small droplets with diameters ranging from 1–150 μm. ULV

• Machines are used for applying pesticides, herbicides, fungicides, sterilizers, and disinfectants amongst other chemicals.

4- By thermal fogging

• Like misting but involving heating of the disinfectant to produce a fine vapor.

• The small particle gives the best penetration and suspension.

• The use of thermal fogging is accepted practice for the final stage of full disinfection programs.

• This method of disinfectant application can be rapid and does not involve large volumes of liquids in buildings where equipment and litter are already installed.

• The drawback of the low volumes that are applied in this way is that there is insufficient penetration of organic matter and porous surfaces for thermal fogging to be effective for primary disinfection, its successful use needs to follow thorough clean out, wash down and spray disinfection.

➡️What Disinfectants can be used?

• Glutaraldehyde-QAC Ammonium mixtures

• QAC

• Virkon S + Fog enhancer (polyethylene glycol)

➡️Not efficient enough or safe enough for common use.

Hydrogen peroxygen, peracetic acid and non-halogen oxygen releaser - which is made up into solution. Has proven high levels of activity against a wide range of common poultry pathogens. It is safe in use for both operators and poultry. As a result, it can be used in terminal disinfection programs or while birds are still in the buildings.

➡️Fumigation:

When allowed, formalin fumigation should be carried out by trained personnel, following local safety legislations and guidelines. Fumigation should be carried out as soon as possible after disinfection; surfaces should be damp and the house warmed to a minimum of 21˚C and an RH more than 65%.The house should be sealed for at least 24 hours, then ventilated well to get rid the irritating formalin odder. Fumigation should be repeated after the litter has been spread.

- HOW DISINFECTION WORKS

Disinfection processes target several sites and cause structural and functional damage to various macromolecules (e.g., proteins, lipids, nucleic acids) of microorganisms.

➡️Biocide Mechanisms of Action

There are four mechanisms of action for this process.

▪️ Oxidizing mode of action. (ORP)

-Biocides with an oxidizing mode of action remove electrons (oxidation) from a substance -in this case - nucleic acids, lipids, proteins and carbohydrates of microorganisms.

Altered structures result in disruption of cell membranes and cell function.

- Oxidizing biocides are widely used and include halogen-based products (e.g., chlorine, iodine) and peroxygen products (hydrogen peroxide, peracetic acid)

➡️Cross-linking or coagulating mode of action:

- Some biocides primarily act by cross-linking or coagulating the amino acids of proteins, (and sometimes nucleic acids bases) to disrupt the structure and function of many microorganisms.

- Disinfectants in this category are aldehydes; alkylating agents, such as ethylene oxide; phenols, and alcohols.

➡️Other structure-disrupting agents:

Several biocides primarily damage lipid membranes. They may directly disrupt membrane proteins or cause increased permeability. The result is leakage of cytoplasm components and cell lysis. Biocides in this category include surfactants (including QACs), biguanides, and organic acids.

• Transfer of energy:

A final mechanism of biocidal action involves the sudden transfer of energy that results in disruption of structure and function. These processes rapidly denature nucleic acids, lipids, and proteins. They include the application of heat and radiation (e.g., ultraviolet light).

- CONSIDERATIONS WHEN SELECTING A DISINFECTION PROCESS

- Selecting an appropriate disinfectant (or disinfection method) is an essential component of any C&D program.

- No single disinfectant is adequate for all situations.

- There are several factors to be considered since they can impact efficacy, possibly cause failure of the disinfection procedures, or result in hazards or injury to personnel or animals.

- Selection will depend on the microorganism(s) suspected, availability, the characteristics of a specific disinfectant or process, environmental factors and safety issues.

➡️MICROORGANISM CONSIDERATIONS

- Selection of a disinfectant begins with the identification of the target microorganism.

- If the organism has not been identified, or a disinfectant is needed for a wide range of organisms, a broad-spectrum approach should be utilized.

➡️Resistance and Susceptibility

- Microorganisms vary in their ability to survive or persist in the environment as well as their susceptibility to disinfection.

- Bacteria: Most vegetative bacteria (e.g., gram-positive, gram-negative) are readily inactivated by disinfectants. Some, such as Pseudomonas aeruginosa and Coxiella burnetii, can have greater resistance to disinfection.

- Mycobacteria and other acid-fast bacteria and bacterial endospores are highly resistant to disinfection, often requiring specific products, increased concentrations, or prolonged contact times.

- Fungi: The vegetative stage of fungal organisms is susceptible to most disinfectants; however, fungal spores are usually quite resistant.

- Viruses: Virus susceptibility is generally related to the presence or absence of a lipid envelope and size.

- Enveloped viruses (e.g., coronaviruses, herpesviruses, orthomyxoviruses, paramyxoviruses, retroviruses) are generally the most susceptible due to their lipophilic nature.

- The lack of envelope for non-enveloped or naked viruses (e.g., adenoviruses, picornaviruses, reoviruses, rotaviruses) makes these pathogens more hydrophilic, resulting in increased resistance.

- Small, non-enveloped viruses (e.g., parvoviruses, picornaviruses, or caliciviruses) demonstrate even greater resistance due to their size and lack of an envelope.

- Prions, the etiologic agents of bovine spongiform encephalopathy, scrapie, and chronic wasting disease, are exceptionally resistant to chemical inactivation.

Source: Clint May and Andrew Kingsbury, Iowa State University (2014).

- Factors affecting the efficiency of Disinfectant

➡️Contact Time

Contact time is critical! Disinfectant products and methods need time to have their effect. This will vary depending on the product or method selected. For example, 70% isopropyl alcohol can destroy Mycobacterium tuberculosis in 5 minutes, whereas 3% phenol requires 2-3 hours.

Poor application or evaporation during high temperatures will impact sufficient contact times. Surfaces must remain wet (for chemical disinfectants) or exposed (for physical methods) for the full contact time. Some chemicals may have residual activity (i.e., QAC) while others may evaporate quickly (i.e., alcohols), especially with high temperatures.

➡️Disinfectant Concentration

Use of the proper concentration of a disinfectant is important to achieve the best results for each situation. Some products will have different dilutions depending on the desired use of the product (i.e., -static versus –cidal action; sanitizing vs. disinfection action).

While using higher concentrations can be more efficacious, routine use may be limited by the degree of risk to personnel, surfaces or equipment, and cost of the chemical.

However, over-dilution of a product will cause the disinfectant to be ineffective against the targeted microorganism(s). The product label will list the best concentration to use for each situation.

➡️Expense. Economic considerations are always important when selecting a disinfectant. Disinfection is generally a cost-effective means of reducing pathogenic organisms. Disinfectants vary in cost, contact time and dilution. Costs should always be calculated as per gallon of use/dilution (per liter of use /dilution) rather than the cost of concentration.

➡️Human Factor – Ease of use another important consideration is ease of use. How easy or hard is the product to apply? Does the product have an offensive odor? Is a long surface contact time, and possible reapplication required?

➡️ENVIRONMENTAL CONSIDERATIONS

Environmental conditions can have a profound effect on disinfection success.

This includes factors such as the organic load, the type of surface, temperature, water hardness, pH or the presence of other chemicals.

The presence of organic matter (e.g., soil, manure, body fluids, bedding) is one of the most important environmental factors to influence disinfection activity! Organic matter provides a physical barrier that protects microorganisms from contact with the disinfectant. Additionally, debris and organic material can neutralize many disinfectants (e.g., chlorine, QACs), reducing the level of active ingredient available to attack microorganisms.

Ultraviolet light applications, including direct sunlight, have limited penetration below the surface of organic matter. Some disinfectants, such as phenols or glutaraldehyde, are less affected by organic matter, and may need to be considered when the complete removal of organic debris is difficult.

➡️Surface Type

Surfaces in animal settings can be quite diverse. They may include various metals, glass, rubber, plastic, concrete, wood, or fabric or woven material (e.g., clothes, nets, and ropes). The type of material or complexity of an item can factor into disinfection efficacy.

Surfaces that are porous, cracked, or pitted (e.g., wood, concrete) or that have complex structure, such as hinges, bends, or crevices can be challenging to disinfect effectively.

Some chemical disinfectants can be incompatible with or corrosive to certain materials or surface types. Some products have been developed for use on porous surfaces, but generally require much longer contact times or higher concentrations.

Alternative or supplemental disinfection methods, such as gaseous or vaporous sterilant products or physical disinfection methods (e.g., drying, ultraviolet light) should be used for treating porous surfaces.

➡️Temperature

Temperature is another important environmental factor that can affect disinfectant efficacy. Considerations should include both the ambient temperature as well as that of the disinfectant solution. The exposure temperature is particularly important if you are disinfecting outdoors (e.g., vehicles). Most chemical disinfectants work best at temperatures above 68o F (20 oC).

Lower temperatures can reduce disinfectant efficacy or solutions may freeze in these conditions.

Conversely, while elevated temperatures can aid in microorganism destruction, it can also accelerate the decomposition or evaporation of a disinfectant.

➡️pH

A pH extreme can be detrimental to microorganisms; however environments that are very acidic or very alkaline can alter the effectiveness of some disinfectants. pH changes in the environment may be caused by organic material, water composition (e.g., water hardness ions), or from other chemical products used. These conditions may change the degree of ionization or dissociation of the active ingredient of a chemical disinfectant or the stability of a solution. Examples include phenolics, hypochlorite, and iodine compounds.

- Factors affecting disinfectant efficacy in the field

1- Biofilms

Comprise extracellular polysaccharide and protein matrices constructed by mono- or multi-species bacterial and/or yeast communities on surfaces and at fluid/gas interfaces.

Biofilm matrix presents a diffusion barrier and a neutralizing environment for some biocides. Biofilm is potentially of great significance in infrequently cleaned and disinfected environments such as animal housing. This protective effect varies with substrate surface, age of biofilm, hydration, fluid shear conditions during biofilm formation, and the mix of microbe species in the biofilm

Biofilm-embedded organisms often show less biocide susceptibility than counterparts dried-on to surfaces they are markedly less susceptible than suspended cells.

In field situations, gross organic soil, biofilm, and post-cleaning residual hydrophobic organic material on surfaces can protect persistent resident pathogens despite regular cleaning and disinfection (C&D), for example in the case of Salmonella in hatcheries.

2-Cleaning agents (usually detergents)

may also show substantial microbicidal activity and may variously interfere or synergies with the action of a subsequently applied disinfectant

3-Drying downtime

One or more days may add substantially to the observed microbicidal effect of C&D procedures, at least for materials where effective drying occurs. Furthermore, drying between applications of cleaner and of disinfectant will allow porous surfaces to absorb more disinfectant in the latter stage

- References

- Alyssa M. West1, Peter J. Teska2, Caitlinn B. Lineback1 and Haley F. Oliver. Strain, disinfectant, concentration, and contact time quantitatively impact disinfectant efficacy. West et al. Antimicrobial Resistance and Infection Control (2018) 7:49 https://doi.org/10.1186/s13756-018-0340-2

- Andrew D. Wales, Rebecca J. Gosling, Harriet L. Bare, Robert H. Davies. Disinfectant testing for veterinary and agricultural applications Department of Pathology and Infectious Diseases, School of Veterinary Medicine, University of Surrey, Guildford, UK (2021) DOI: 10.1111/zph.12830

- FAD PReP/NAHEMS Guidelines: Cleaning & Disinfection (2014). http://www.aphis.usda.gov/fadprep. - Centre for Food Security & Public Health. Disinfection. 101 key principals of cleaning and disinfection for animal settings. Iowa state University. Collage of Veterinary Medicine ( 2023).

- Centre for Food Security & Public Health. Disinfectant 101 key principals of cleaning and disinfection for animal settings. Iowa state University. Collage of Veterinary Medicine 2023.

- Ford WB. Disinfection procedures for personnel and vehicles entering and leaving contaminated premises. Rev. sci. tech. Off. int. Epiz. 1995:14(2):393-401.

- Luyckx, K., VanWeyenberg, S., Dewulf, J., Herman, L., Zoons, J., Vervaet, E., Heyndrick:x:, M., De Reu, K. On-farm comparisons of different cleaning protocols in broiler houses. Poultry Science 2015:94, 1986-1993.

- Maillard J. Ch 3: Factors affecting the activities of microbiocides. In: Russell, Hugo & Ayliffe's: Principles and Practice of Disinfection, Preservation, and Sterilization, 5th edition. Edited by: AP Fraise, JY Maillard, SA Sattar. 2013. Blackwell Publishing. p71-86.

- Maillard, J. Y. 2002. Bacterial target sites for biocide action. J. Appl. Microbiol. 92(Suppl.):16S–27S.

- Maris P. Modes of action of disinfectants. Rev. sci. tech. Off. int. Epiz. 1995:14(1):47-55.

- McDonnell GE. Ch 2: Physical disinfection. In: McDonnell GE. Antisepsis, Disinfection and Sterilization: Types, Action and Resistance. Washington DC: ASM Press. 2017 p61-84

- McDonnell GE. Ch 3: Chemical disinfection. In: McDonnell GE. Antisepsis, Disinfection and Sterilization: Types, Action and Resistance. Washington DC: ASM Press. 2017 p85-165.

- National Institute for Occupational Safety and Health (NIOSH). Sodium hydroxide. Available at https://www.cdc.gov/niosh/topics/sodium-hydroxide/. Disinfection 101 2023-0628-final.docx © CFSPH 2008-2023 42

- National Pesticide Information Center. Antimicrobials. Topic Fact Sheet. Available at: http://npic.orst.edu/factsheets/antimicrobials.html.

- National Pesticide Information Center. Selecting the Right Antimicrobial Product. Available at: http://npic.orst.edu/ingred/ptype/amicrob/select.html.

- Portner JA. Guidelines for reducing pathogens in vet hospitals: Disinfectant selection, cleaning protocols, and hand hygiene. Comp Contin Edu for Vets 2010;32(5): E1-11.

- Quinn PJ, Markey BK. Disinfection and disease prevention in veterinary medicine. In: Block SS, editor. Disinfection, sterilization and preservation. 5th edition. Philadelphia: Lippincott, Williams & Wilkins. 2001; pp1069-1103.

- Quinn PJ, Markey BK, Leonard FC, FitzPatrick ES, Fanning S, Hartigan PJ. Ch 94. Disinfection, biosecurity and other aspects of disease control. In: Veterinary Microbiology and Microbial Disease, 2nd edition. 2011 Blackwell Publishing LTD. Wiley-Blackwell, West Sussex. p851-889.

- Quinn PJ, Markey BK, Leonard FC, Fitz Patrick ES. 2021. Ch. 52. Disinfection and biosecurity and the prevention and control of disease in veterinary medicine. IN: GE McDonnell, J Hansen (Eds.), Block's Disinfection, Sterilization, and Preservation. 6th edition. Philadelphia:Wolters Klewer Health. 2021.

- Rutala WA, Weber DJ. Selection of the ideal disinfectant. Infect Control Hosp Epidemiol. 2014 Jul;35(7):855-65.

- Stringfellow K, Anderson P, Caldwell D, et al. Evaluation of disinfectants commonly used by the commercial poultry industry under simulated field conditions. Poultry Science 2009;88:1151-1155.

- Stull JW, Bjorvik E, Bub J, Dvorak G, Petersen C, Troyer HL. 2018 AAHA infection control, prevention, and biosecurity guidelines. J Am Anim Hosp Assoc. 2018 Nov/Dec;54(6):297-326. https://www.aaha.org/aaha-guidelines/infection-control-configuration/aaha-infection-control-prevention-and-biosecurity-guidelines/.

- Traverse M, Aceto H. Environmental cleaning and disinfection. Vet. Clin. North Am. Small Anim. Pract. 2015 Mar;45(2):299-330.

- Van Kessel J, Strom S, et al. Time and temperature requirements for heat inactivation of pathogens to be applied to swine transport trailers. J Swine Health Prod. 2021:29(1) 19-28.

- Iowa State University, College of Veterinary Medicine. The Center for Food Security and Public Health (2024). Information on Cleaning and Disinfection Overview. www. Poultrybiosecurity.org